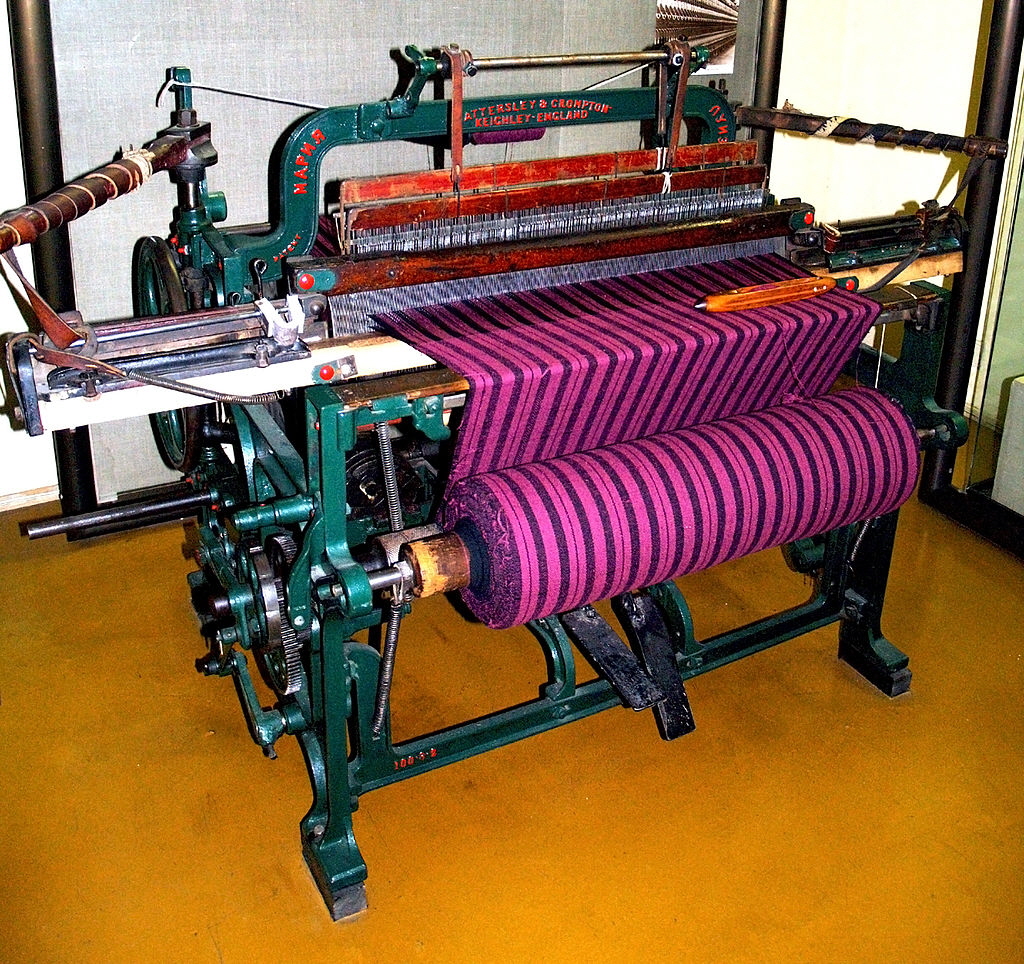

With handlooms, foot pedals lifted and lowered the warp (tightly strung threads) while the weft (weaker threads) were drawn in between the warp threads, creating cloth. Power looms worked very similarly to the original handlooms. The original design was flawed, and needed improvements. The power loom was a steam-powered loom that mechanized the process, reducing the need for humans to oversee the weaving process. 491 Issued NovemWilliam Crompton of Taunton, Massachusetts model constructed before patent date ID Number TE.T11411.001 accession number 89797 catalog number T11411.001 patent number 491 Object Name loom patent model Object Type Patent Model model Physical Description iron (overall material) brass (overall material) steel (overall material) wood (overall material) leather (overall material) Measurements approx.: 24 in x 14 in x 12 in 60.96 cm x 35.56 cm x 30.48 cm inventor's residence United States: Massachusetts, Taunton associated place United States: Massachusetts, Taunton Related Publication Janssen, Barbara Suit.A loom is a device designed to weave threads into cloth. After 1859, the Crompton Loom Work became one of the two largest fancy loom manufacturers in the United States.

Like his father, George was an inventor and patented many improvements for the loom. upon the Crompton loom or looms based on it, are woven every yard of fancy cloth in the world.” In 1849, William’s health declined and his son, George, carried on the business. In his book, American Textile Machinery, John Hayes quotes the Committee on Patents of the United States House of Representatives, 1878: “. This he accomplished in 1840, and it was considered an important landmark for the woolen industry. He met with success when the Middlesex Mills in Lowell, Massachusetts, invited him to alter his fancy cotton loom for the weaving of woolen fabrics. Later in 1839 Crompton emigrated with his family back to the United States in order to promote his looms. He entered into cotton manufacture with John Rostran, and took out a British patent for his loom under Rostran’s name. The mill failed in 1837 and Crompton went back to England. At this textile mill he designed a loom to weave a new more complex patterned fabric.

He was thirty when he came to Taunton, Massachusetts, and was employed by Crocker and Richmond.

#POWER LOOM HOW TO#

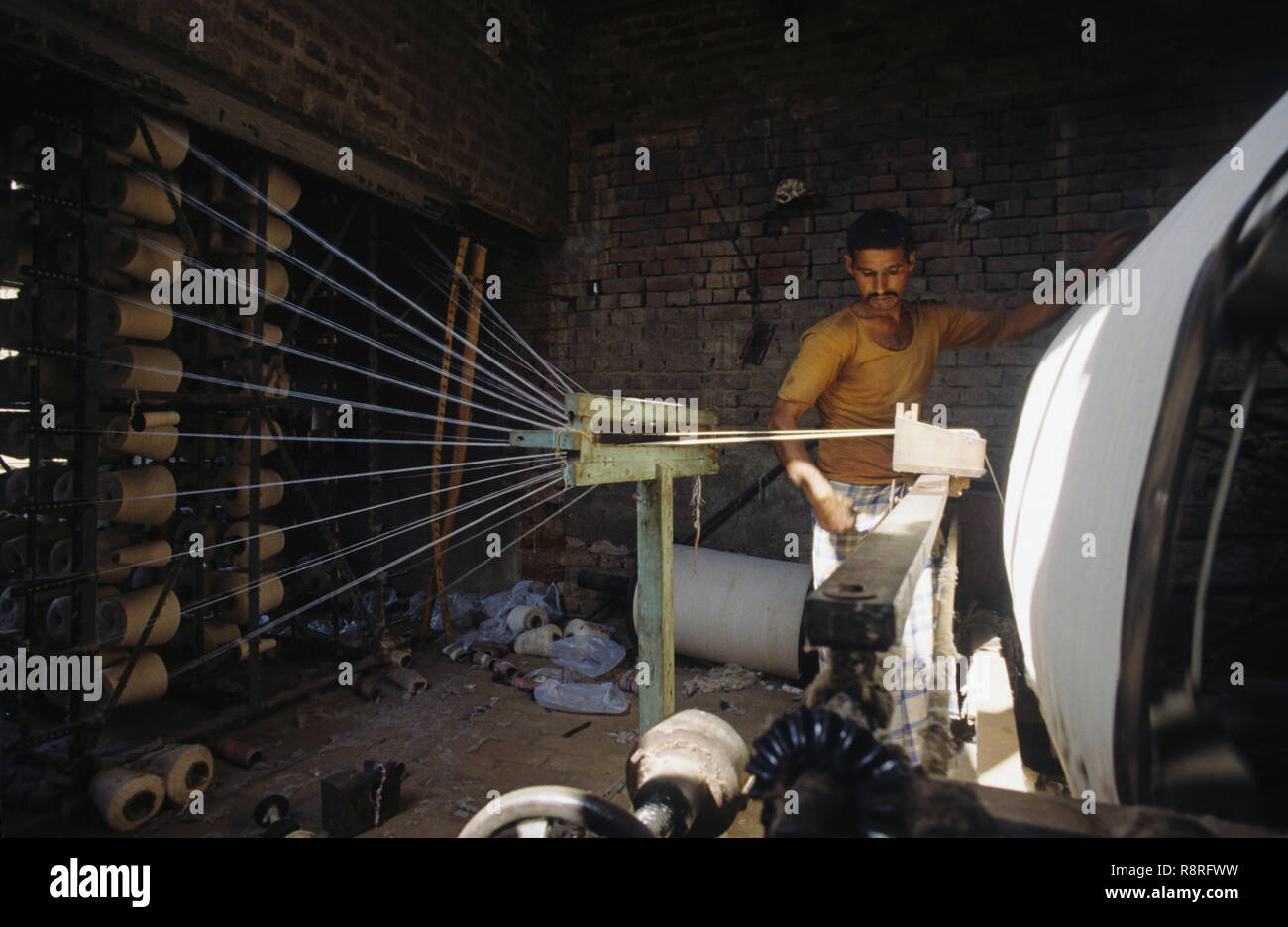

He was taught how to weave on a cotton hand loom and learned the trade of a machinist. In 1806 William Crompton was born in the textile mill town of Preston, England. Now more elaborate designs could be easily woven on power looms. In his patent, an endless pattern chain was used, upon which rollers or pins could be variously placed to engage the harness levers (as had the cams) but which allowed any number of harnesses to be used and easily permitted the changing of patterns. Crompton’s invention solved both of these problems. In order to vary the pattern, the cams had to be laboriously changed. This arrangement limited the number of harnesses that could be utilized, which in turn limited the complexity of patterns that could be woven. Object Details inventor Crompton, William Description Before William Crompton’s 1837 patent for a fancy power loom was adopted, the harnesses of power looms were controlled by cams. Eliot Elisofon Photographic Archives, African Art.

0 kommentar(er)

0 kommentar(er)